Grand Prints is dedicated towards development and enhancement of its pharmaceutical printing and packaging solutions. We are highly committed to print innovative materials that make it easier for your customers to get vital information and provide superior quality pharma packaging solutions. We follow ISO standards to achieve consistency in all print processes. In short, Grand Print is the all-in-one solution for pharmaceutical, health-care and medical printing and packaging.

The role of products produced in pharmaceutical industry is critical. It requires your attention and care as well as control during the manufacturing process. Every step involved in the process from manufacturing to printing of pharmaceutical labels needs a proper planning. Grand Prints is one of the leading pharmaceutical printing companies that offers reliable and cost-effective printing solutions to pharma companies.

We are also the best pharmaceutical label manufacturers as we understand the importance of custom label printing that is essential in pharmaceutical industry. Hence, we thrive to provide best-in-class pharmaceutical label printing solutions to our clientele. The major functions of packaging include:

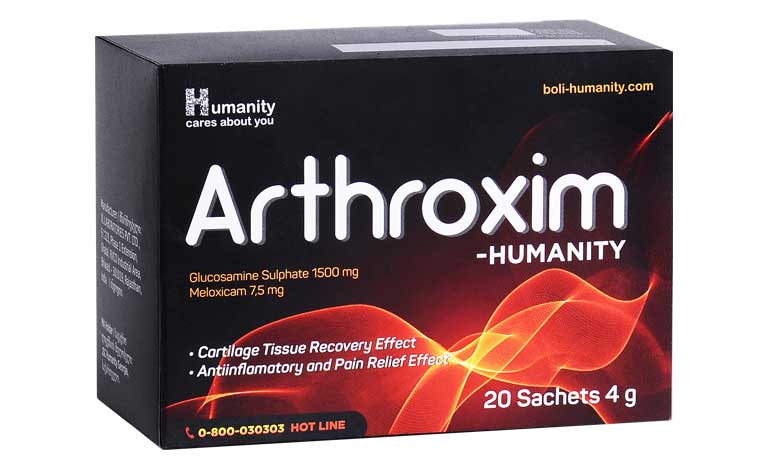

Package Testing - We also do package testing such as drop test, vibration test, shock test, inclined impact test and revolving drum test for their safer long journeys.

Grand Prints is a renowned pharmaceutical printing and packaging solution provider in India with the experience attained by serving for 40 years in this industry. We have some of the finest medical printers to print custom labels, cartons and other assets required by its clientele. Packaging of pharmaceutical products is critical, and this is why pharma companies require an expert like Grand Prints to serve them better. Some of the most obvious reasons to go with Grand Prints are as follows:

Unlike other industries, turnaround time matters a lot in pharmaceutical industry. Being a pharmaceutical labels manufacturer and a medical packaging company, Grand Prints deliver labeling solutions in short turnaround time. The shorter turnaround time enables the fast launches and customization addressing the requirements of the targeted audience i.e. the patient population. We make use of best-in-class machines to carry out the label printing process swiftly. We assure you best printing quality and fastest turnaround time.

Grand Prints is consistently keeping pace with the advancing technology. We use latest and modern technology to provide best pharmaceutical printing, labeling and packaging services to our clientele. Nowadays, 3D printing technology is used in pharmaceutical industry also, which has opened new opportunities for pharmaceutical researches and biotechnology applications. We make use of right printing technology and deliver what our clients need. Our technology offers unparalleled flexibility, faster delivery time and exceptional printing capabilities. We are well versed with different printing techniques fulfilling the requirements of each and every client coming to us.

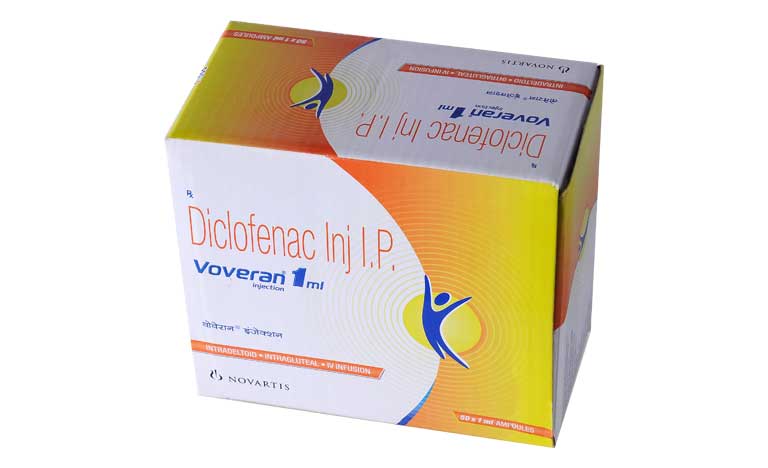

Grand Prints helps you mitigate the risk of forgery by adding security features to your products, thereby preserving your brand value. We have a wide range of security options available that can be used independently and can also be combined with other multi-layer solutions. The latest security solutions include concepts like overt, semi-covert and covert. The security features added to your product are totally unmatched and provides you utmost privacy and safety, allowing manufacturers to stay a step ahead of their competitors.

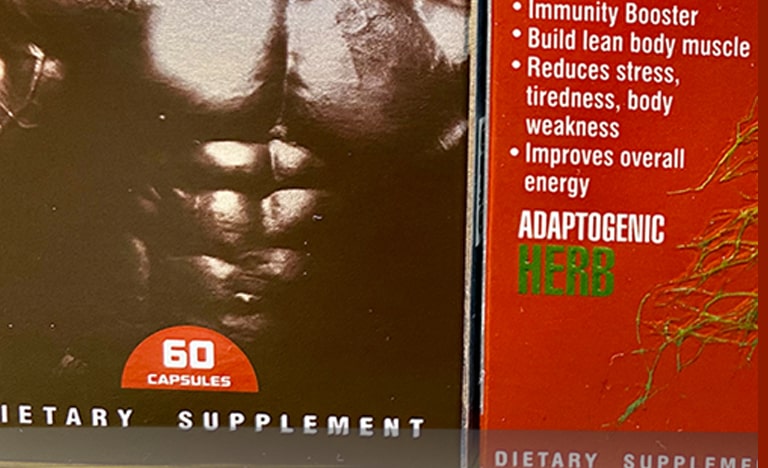

The customized pharma printing and packaging solutions are trending these days. We provide you a competitive edge by helping you create a brand reputation by using our customized printing solutions. You get complete control over the design of your print. The customized packaging and cartons can be delivered at much affordable rates in fastest turnaround time.

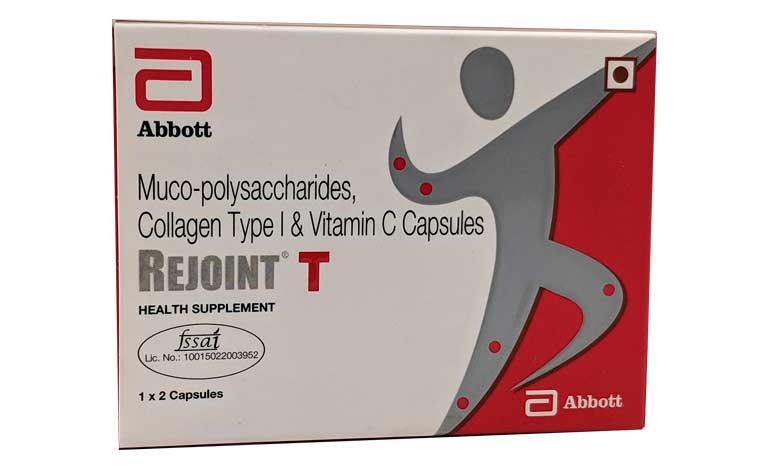

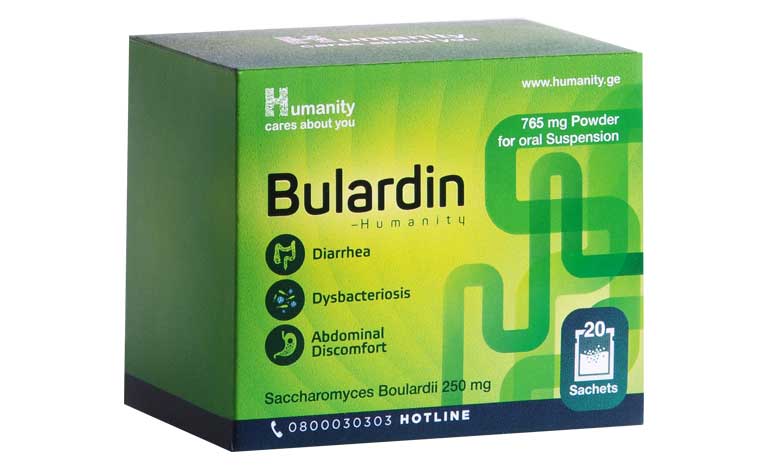

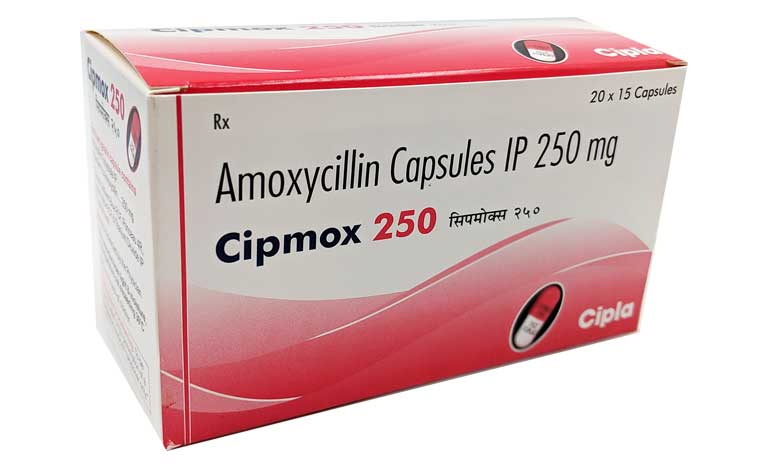

If you are into pharmaceutical industry, you must be aware of importance of pharmaceutical printing and packaging companies. Quality packaging of pharmaceutical products is really important. A good packaging with legible and clear text is a signature of quality product.

Custom label printing plays a major role in commercialization of goods, especially in the pharmaceutical industry. Pharma products such as life-saving drugs specify their ingredients and composition on the packaging. Pharma labels manufacturers play a significant role in packaging of pharmaceutical products. Any mistake can lead to serious trouble to the product company. The data printed on custom product labels must be clear and legible enough to be read easily by the physicians and customers.

Understanding the criticalness of printing quality, healthcare printing industry have come up with latest technology. But, printing for pharma companies is bit different from companies in other industries. In case of pharma printing, the text and other informatory images to be printed on carton require extensive proofreading with ability to meet the industry standards.

The pharma companies need to meet various requirements and demands of their elite customers. For example: European drug manufacturers and suppliers look for Braille embossment on the packaging. Braille embossing is mandatory for the medical product packages in Europe, which in turn increases the pressure on pharmaceutical printing companies too.

Safety and security while printing and packaging of pharmaceutical products are other critical aspects that must not be overlooked if you are really following the industry standards. Pharma printing is different from others and have a number of challenges for printing and packaging companies too.

The effectiveness of pharmaceutical products largely depends on the quality of their packaging. This is why most of the pharma companies are cautious while choosing packaging material for drug product. It’s not at all an easy job as there is a variety of materials available to choose from. The material chosen must act as an air barrier, moisture barrier, light barrier and should have chemical-friendly properties.

The material chosen must retain physical properties of the drugs and provide protection from any damage or breakage incident. This means that the drugs must not be deformed due to rough handling while transporting them over long distance.

In short, the material chosen for pharmaceutical packaging process must shield the content from physical and biological entities, and undesirable and adulterating chemicals.

Printing and packaging in pharmaceutical industry is very critical. You need to ensure that the printing must be done keeping quality and standards in mind while the packaging material used must be able to protect the drug from getting damaged, under all circumstances.

We use 3-D printing technology while printing the packaging for pharmaceutical products.

Our solutions include concepts like overt, semi-covert and covert.

Custom labelling is really important in pharmaceutical industry. We do it for you. Every step involved in the process including the packaging part is monitored properly. We even do serialization for you to avoid any counterfeiting of products.

The time taken to complete an order depends upon the order size. It hardly takes us a few days to complete the order.

The amount charged for Pharmaceutical Printing depends upon the size of order. Apart from this, the shape & size of box and security features you want in the packaging also influence the price of your order.